Concrete is renowned for its durability and strength, making it a worldwide cornerstone of construction projects. However, even this seemingly indestructible material can succumb to damage over time, and spalling is one of its most common issues. Spalling concrete occurs when the surface of concrete deteriorates, resulting in the flaking, chipping, or breaking away of concrete layers. This article will delve into the causes, effects, and repair methods of concrete spalling.

Concrete Spalling Causes

Freeze-Thaw Cycles

In regions with fluctuating temperatures, water can seep into concrete pores. When this water freezes, it expands, exerting pressure on the concrete and causing it to crack and spell.

Corrosion of Reinforcing Steel

When steel reinforcement within concrete corrodes due to exposure to moisture and oxygen, it expands, leading to internal pressure and eventual spalling of the concrete cover.

Chemical Exposure

Exposure to chemicals such as de-icing salts, acids, and industrial pollutants can accelerate concrete deterioration, leading to cement spalling over time.

Poor Construction Practices

Improper mixing of concrete, inadequate curing, and insufficient cover over reinforcing steel can all contribute to weakened concrete, increasing the likelihood of spalling.

Abrasion and Wear

High-traffic areas subjected to constant abrasion from vehicles, foot traffic, or machinery can wear down the concrete surface, spalling over time.

Alkali-Aggregate Reaction (AAR)

Specific reactive aggregates used in concrete mixtures can undergo a chemical reaction with alkalis present in the cement paste, resulting in the expansion and cracking of concrete, ultimately leading to spalling.

Overloading

Excessive loading beyond the design capacity of a concrete structure can cause stress and deformation, leading to cracking and spalling, particularly in areas of concentrated stress, such as support columns or beams.

Thermal Shrinkage

Rapid temperature fluctuations can induce thermal stresses within the concrete, causing it to shrink and crack, ultimately leading to spalling, especially in regions with extreme temperature variations.

Poor Drainage

Inadequate drainage systems or improper slope gradients can lead to water accumulation on the surface of concrete structures. Prolonged exposure to moisture can accelerate the deterioration process, causing spalling due to freeze-thaw cycles and corrosion.

Poor Quality Materials

The use of substandard or contaminated materials in concrete mixtures, such as aggregates containing organic matter or excessive clay content, can compromise the strength and durability of concrete, leading to premature spalling.

Effects of Concrete Spalling

Structural Weakness

Spalling compromises the structural integrity of concrete, reducing its load-bearing capacity and potentially leading to structural failure if left untreated.

Aesthetic Deterioration

Spalling creates an unsightly appearance, detracting from the visual appeal of buildings, bridges, and other concrete structures.

Safety Hazards

Falling concrete debris poses a significant safety risk to pedestrians and vehicles, particularly in high-traffic areas.

Environmental Degradation

Concrete spalling contributes to environmental degradation by releasing particles and contaminants into the surrounding environment, impacting air and water quality.

Loss of Functionality

Spalling can impair the functionality of concrete structures, affecting their ability to perform intended functions such as load bearing, water containment, or traffic flow.

Financial Costs

Repairing spalled concrete can be expensive, requiring labour, materials, and equipment. Additionally, the downtime during repairs may result in economic losses for businesses and disruptions to public services.

Liability Risks

Spalled concrete poses liability risks to property owners and managers, increasing the likelihood of accidents and injuries due to falling debris or compromised structural integrity.

Deterioration of Surrounding Materials

Concrete spalling can lead to the deterioration of adjacent materials such as steel reinforcements, masonry, or waterproofing membranes, exacerbating the overall damage and repair costs.

Functional Impairment

Concrete spalling can impair the functionality of infrastructure such as bridges, dams, and roads, restricting traffic flow, impeding water flow, and compromising overall performance.

Concrete Spalling Repair

Surface Patching

For minor spalling, surface patching using specialised repair mortars can be effective. This involves cleaning the affected area, removing loose concrete, and applying the repair mortar to restore the surface.

Epoxy Injection

Epoxy injection is used to repair cracks and delamination within concrete by injecting epoxy resin into the affected areas. This method strengthens the structure and prevents further deterioration.

Reinforcement Coating

Applying a protective coating or sealant to the concrete surface can help prevent moisture infiltration and corrosion of reinforcing steel, reducing the risk of spalling.

Structural Repair

More extensive repair techniques may be necessary for severe spalling or structural damage, such as replacing deteriorated concrete sections or reinforcing the structure with additional steel.

Shotcrete Application

Shotcrete, a specialised concrete mixture applied with pneumatic pressure, can be used to repair large areas of spalled concrete quickly and efficiently, providing structural reinforcement and surface restoration.

Cathodic Protection

Cathodic protection systems can be installed to slow down the corrosion process of reinforcing steel in concrete, extending the structure’s service life.

Crack Stitching

In cases where cracks in concrete cause spalling, crack stitching involves drilling holes across the crack and inserting metal rods or stitching bars bonded with epoxy resin to stabilise and reinforce the damaged section.

Carbon Fibre Reinforcement

External carbon fibre reinforcement systems can reinforce and strengthen concrete structures, especially in areas prone to spalling and structural weakness. This provides a cost-effective and durable solution for repairs.

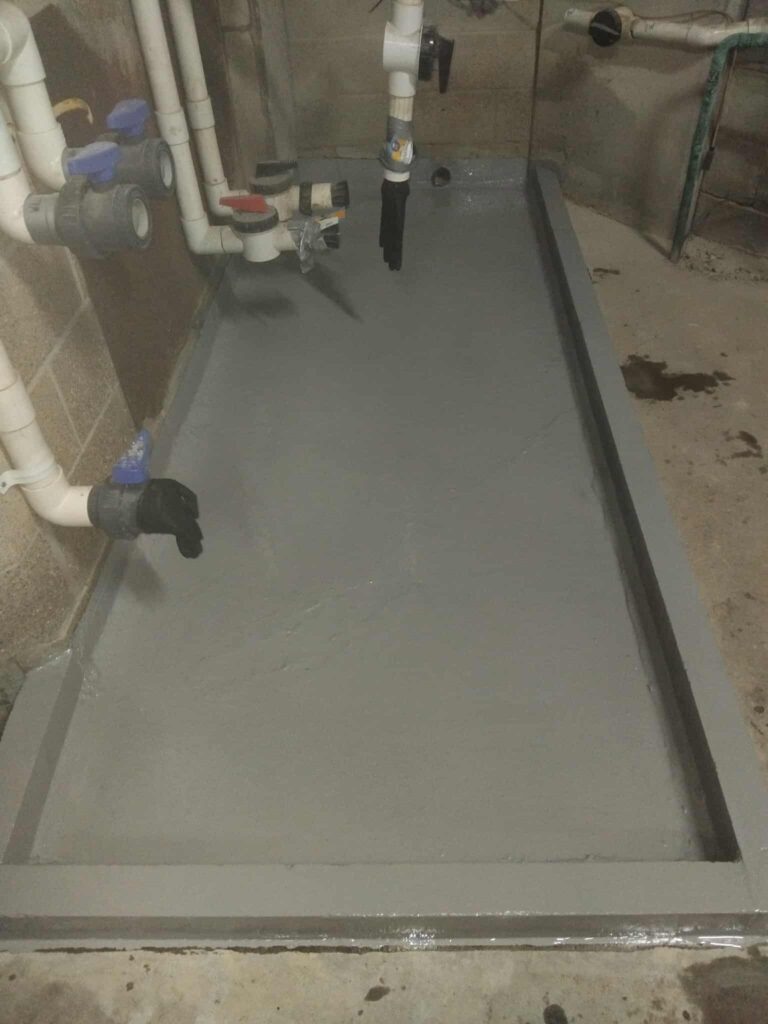

Surface Coating and Waterproofing

Applying specialised surface coatings and waterproofing membranes can protect concrete surfaces from moisture infiltration, chemical exposure, and abrasion, preventing spalling and prolonging the structure’s lifespan.

Diamond Grinding

Diamond grinding involves using specialised equipment with diamond-tipped blades to grind and smooth concrete surfaces, removing surface irregularities and spalled areas and restoring surface flatness and texture.

Polymer Overlay

Polymer overlays are thin, high-strength coatings applied to concrete surfaces to repair spalling, fill cracks, and provide a protective barrier against moisture, chemicals, and abrasion, enhancing the durability and longevity of the structure.

Trust S&S Remedial for Your Concrete Repair Needs

Are you facing concrete spalling issues and in need of reliable repair solutions? Look no further than S&S Remedial. With our expertise, advanced techniques, and commitment to quality, we’re your trusted partner for restoring the integrity and durability of concrete structures. Contact us today to schedule a consultation and experience the difference with S&S Remedial. Your concrete repair needs in Brisbane and Gold Coast are in good hands.