When you spot a crack in a concrete slab, it’s tempting to reach for a tube of sealant and call it a day. But if that crack is more than just cosmetic—especially if it’s widening, running deep, or affecting load-bearing areas—then you’re dealing with a structural issue. And that’s where professional intervention becomes critical.

Structural cracks in concrete slabs are often symptoms of deeper problems: soil movement, poor compaction, water intrusion, or even rebar corrosion. While a hairline crack in concrete slab might seem harmless, it can quickly evolve into a serious hazard if left untreated. That’s why pros don’t just patch the surface—they diagnose the root cause and apply long-term solutions like concrete slab injection or concrete injection repairs.

Repairing a Concrete Slab

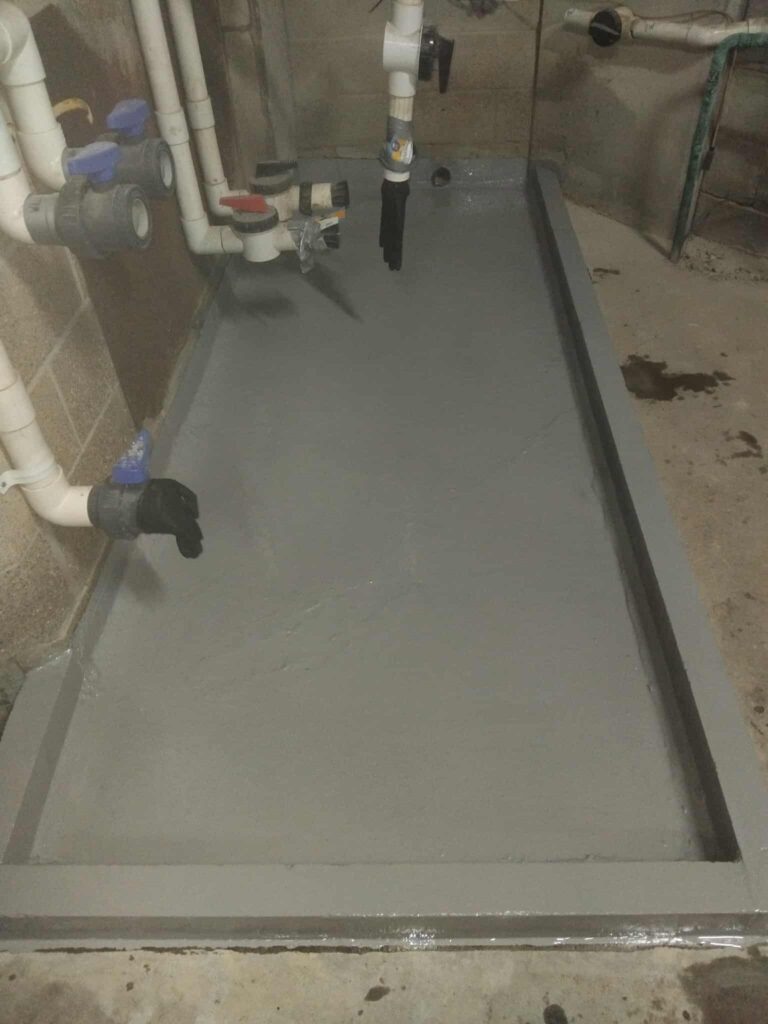

One of the most effective methods Brisbane waterproofing professionals use is epoxy or polyurethane slab injection. This process involves injecting high-strength epoxy or polyurethane resins deep into the crack in concrete slab. Unlike surface fillers, these materials bond the fractured concrete from within, restoring structural integrity and preventing further movement. Epoxy is typically used for dry, load-bearing cracks, while polyurethane is ideal for sealing active leaks or moisture-prone areas.

Before any concrete slab repair or chemical slab injection begins, SS Remedial thoroughly assess the slab for concrete cracks using tools like crack gauges, moisture meters, and sometimes even ground-penetrating radar. This ensures they’re not just treating the symptom but addressing the underlying issue—whether it’s subsidence, hydrostatic pressure, or thermal expansion.

Another reason DIY fixes often fall short is improper surface prep. Professionals know that successful concrete slab repair starts with grinding, cleaning, and sometimes routing the crack to create a proper bonding profile. Skipping this step can lead to delamination, where the patch peels away from the slab under stress.

More Severe Cases

In more severe cases, repairing a concrete slab may involve doweling, rebar stitching, or even partial slab replacement. These are not weekend projects—they require structural calculations, specialized tools, and compliance with building codes. A DIY patch might hide the problem temporarily, but it won’t stop the crack from spreading or the slab from settling unevenly.

Licensed Brisbane waterproofer also understand that not all crack in concrete slabs are created equal. A hairline crack in concrete slab may be monitored over time, while a diagonal or stair-step crack near a column or wall could signal foundation movement which need an immediate concrete foundation injection. Knowing the difference is key to choosing the right concrete slab repair method—and avoiding costly mistakes.

Ultimately, the slab for concrete cracks isn’t just about aesthetics—it’s about safety, longevity, and performance. If you want peace of mind and a repair that lasts, trust the pros. We don’t just fix a crack in concrete slab in Brisbane—our chemical slab injection professionals restore the strength beneath your feet.

Ready to Fix Your Concrete Slab?

Whether you’re dealing with hairline cracks or structural damage, our team can help you choose the right slab injection solution and ensure long-term durability. Let’s tailor the repair to your site.

💉 Resin Injection Options for Concrete Slab Cracks

1. Epoxy Injection Grouting (Structural Bonding)

- Best for: Dry, dormant cracks in load-bearing slabs

- How it works: High-strength epoxy is injected into the crack under pressure, bonding the concrete back together

- Benefits:

-

- Restores structural integrity

- Prevents further movement

- Compatible with rebar reinforcement

2. Polyurethane Injection (Water Sealing)

- Best for: Active or leaking cracks, especially in basements or wet environments

- How it works: Expands upon contact with moisture to seal the crack and block water ingress

- Benefits:

-

- Flexible and water-reactive

- Ideal for slab-on-grade or below-grade repairs

- Can be used in conjunction with waterproofing membranes

3. Hybrid Systems (Epoxy & Polyurethane Injection)

- Best for: Cracks that require both structural repair and water sealing

- How it works: Polyurethane is injected first to stop leaks, followed by epoxy to restore strength

- Benefits:

-

- Dual protection

- Common in commercial and civil slab repairs

Long-Term Concrete Repair & Waterproofing Solutions – Brisbane & Gold Coast

At SS Remedial, we deliver long-lasting concrete slab injection repair and waterproofing solutions designed specifically for your Gold Coast property. Our team takes the time to assess site conditions, identify underlying causes, and implement tailored fix a crack in concrete slab strategies that restore strength, stability, and protection against moisture damage.

✅ Site-Specific Assessment

Reinforcement Strategies

Once the cause is identified, we use proven reinforcement techniques to strengthen and stabilise your concrete slab:

- Rebar or carbon fibre stitching to bridge and lock cracks for lasting stability.

- Doweling to securely connect new concrete to existing slab sections.

- Overlay systems to resurface, seal, and protect repaired areas for long-term durability.

Waterproofing Integration

If your slab is exposed to water or moisture, we integrate advanced waterproofing systems to prevent future deterioration:

- Penetrating sealers to block water absorption.

- Negative-side waterproofing for internal moisture control and long-term resistance to dampness.

📋 Compliance & Documentation

All repair and waterproofing work is carried out to QBCC waterproofing standards, ensuring compliance for resale, insurance claims, or council approvals. You’ll receive complete documentation for peace of mind and future reference.

Protect your investment with tailored, compliant, and long-term concrete repair solutions on the Gold Coast.

Contact our local team today for an on-site assessment and expert advice.