Introduction

Concrete structures often develop cracks due to stress, shrinkage, or environmental exposure. Two common repair methods are epoxy concrete patching and crack injection (epoxy or PU). While both restore durability, they serve different purposes

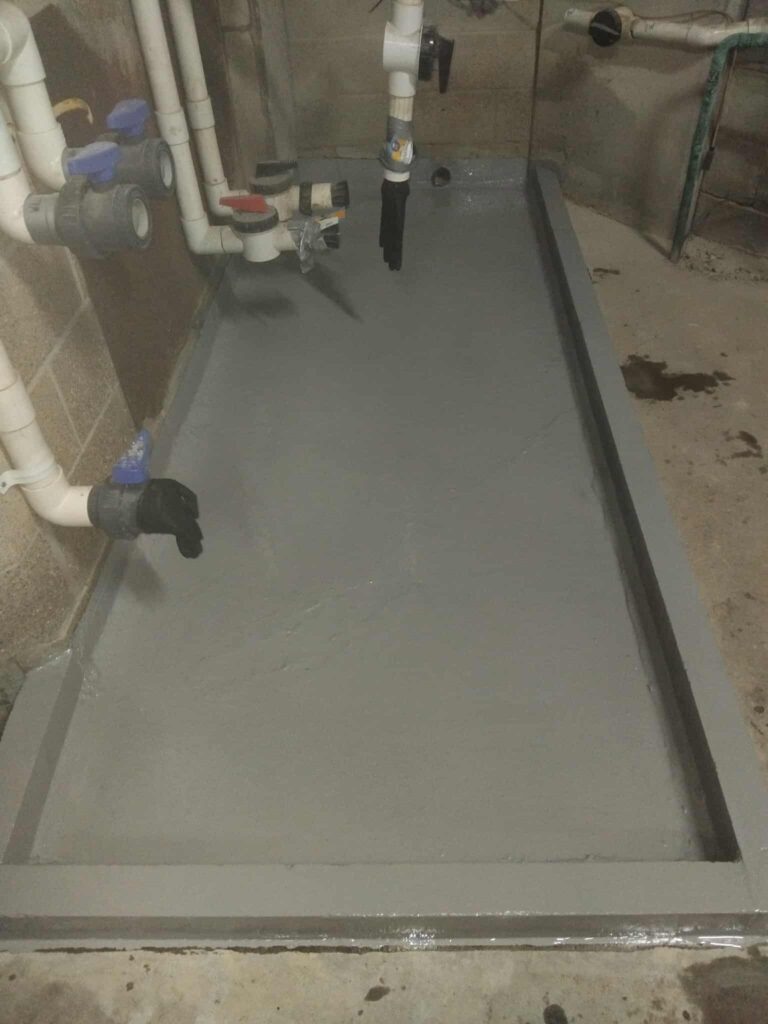

Resin Crack Injection on Concrete

What It Is:

A structural repair method where epoxy or polyurethane resin is injected under pressure into cracks.

Bonds the concrete internally, restoring load‑bearing capacity.

Best For:

Structural cracks in foundations, beams, columns, and slabs.

Waterproofing against leaks in basements, reservoirs, and retaining walls.

Advantages:

- Penetrates deep into cracks, sealing them completely.

- Epoxy injection can “weld” concrete back together structurally.

- Polyurethane injection provides flexibility for moving cracks and water sealing.

Limitations:

Requires specialized equipment and trained contractors.

More costly than surface patching.

Foam Crack Injection

Epoxy Concrete Patching

What It Is:

- A surface repair method using a two‑component epoxy resin mixed with fillers.

- Applied directly to cracks, holes, or spalls on exposed concrete surfaces.

Best For:

- Non‑structural cracks, chips, and surface defects.

- Floors, walls, and slabs where appearance and surface where cracks become an eyesore to owner or visitors.

Advantages:

- Strong chemical bond to concrete.

- Resistant to shrinkage, chemicals, and heavy traffic.

- Easy to apply for small‑to‑medium defects.

Limitations:

- Works only on accessible surfaces.

- Not suitable for deep, structural cracks.

Epoxy crack patching

Choosing the Right Method for Concrete Crack Repair

- Use epoxy concrete patching for repairing surface defects such as chips, spalls, or cosmetic cracks, including patching cracks in concrete walls where durability and appearance matter.

- Use resin crack injection (epoxy or polyurethane crack injection) for structural cracks or when waterproofing and safety are critical.

- For compliance in Queensland, always hire QBCC‑licensed remedial waterproofing contractors to ensure all repairs meet Australian Standards

Key Risks of Epoxy Concrete Patching

Application Risks

- Surface preparation is critical → If the concrete is not cleaned, dried, and profiled properly, the patch may fail.

- Moisture issues → Epoxy does not bond well to damp or high‑moisture slabs, leading to delamination.

- Crack size limitations → Works best for cracks up to ½ inch wide; larger or structural cracks require injection or alternative methods.

Cost & Longevity Risks

- If applied incorrectly, repairs may fail prematurely, leading to repeat costs.

- Over‑reliance on epoxy patching for structural issues can give a false sense of security if deeper problems aren’t addressed.

Structural Risks

Takeaway:

Epoxy concrete patching is ideal for surface‑level repairs or patching concrete cracks is best only when crack is consider as cosmetic concern, while concrete crack injection is the go‑to solution for structural and remedial waterproofing needs. Choosing the right method depends on the depth, severity, and purpose of the repair.

Always use QBCC‑licensed remedial contractors (in Queensland) or equivalent local licensing to ensure compliance.